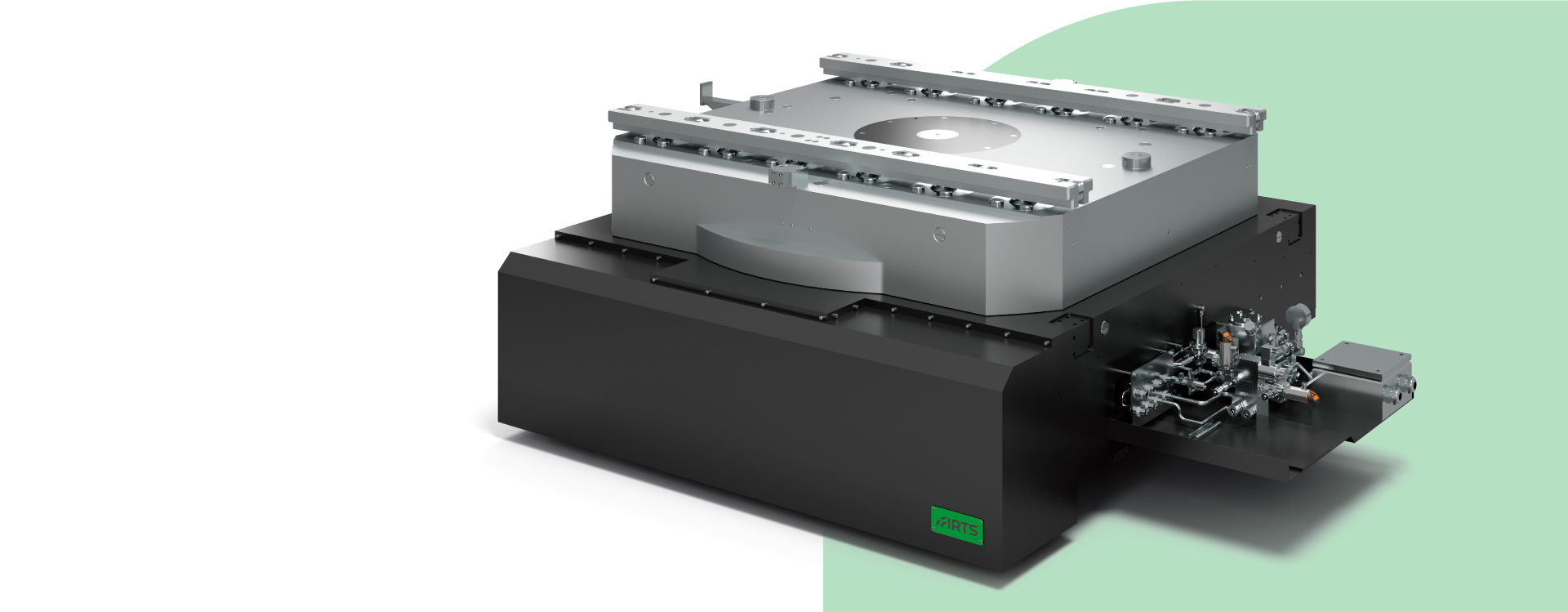

IRTS

ABOUT US

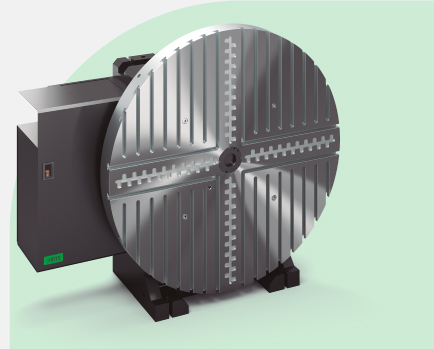

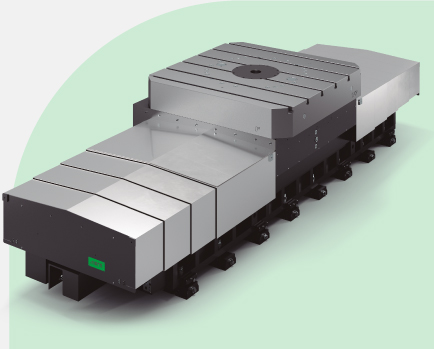

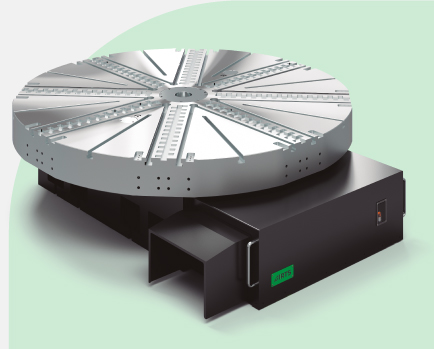

IRTS. S.L. is dedicated to the design, manufacture and distribution of rotary tables mainly aimed at manufacturers of machining centres, milling and boring machines.

Thanks to the extensive experience gained over the years in the machine tool sector, IRTS offers its clients customized solutions to their requirements. Our engineering and production means we offer an unbeatable service.

Our aim is to meet the needs of machine tool builders providing a high-quality product, developing and adapting them to their requirements.